ColdMetalFusion with QLS enables cost-effective serial production of up to 100,000 parts per year. With this process, you can:

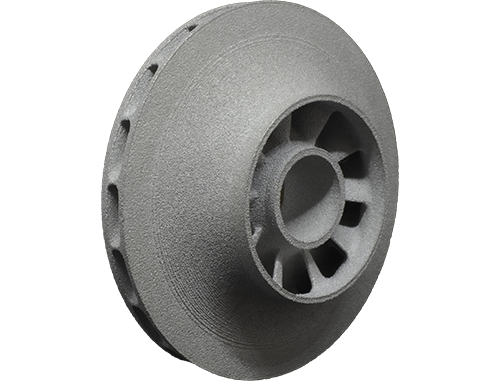

ColdMetalFusion (CMF) is a proven process that’s very similar to metal injection molding but with the added design freedom and fast production typically associated with 3D printing. Utilizing patented metal powder feedstock from Headmade® Materials, this unique feedstock has a thin polymer coating over each metal particle used to bond particles together during the sintering process. Each particle is sintered at a low temperature in Nexa3D’s fast-cycle QLS printers, and once printed, parts go through a validated debinding and sintering process to burnout and remove the polymer, resulting in fully-metal components.

Daily Output

12-Hour Cycle

12-Hour Cycle

ColdMetalFusion process uses high-quality feedstock from Headmade Materials®

Known for its high strength and light weight, titanium also offers good corrosion resistance and biocompatibility, making it a great solution for aerospace and medical applications. Titanium alloy Ti6Al4V (Grade 5) is the most commonly used Titanium alloy globally.

One of the world’s most loved metals, Stainless Steel 316L is typically used for mechanical components with high demands for corrosion resistance. This material is suitable for operation up to 842 °F (450 °C) and can be easily welded.

A stainless and hardenable alloy coupling great mechanical properties and high wear resistance with corrosion resistance. Typically used for industrial applications.

A hardenable, high-speed steel with well-balanced toughness, wear resistance and high hardness. This material is mainly used for abrasive tools, cold work punches, dies, and other cutting applications.

Want to discuss about how metal 3D printing can be used in your application? Fill out the form to and we will be in touch with you shortly!

© 2023 P3 Additive. All rights reserved.